MAIN STANDARDIZED DOCUMENTS

-

MIL-STD-810H

-

MIL-STD-883

-

MIL-STD-202

-

IEC 60529

-

SAE J1455

-

JESD22-A101C

COMMON INDUSTRIES THAT UTILIZE SAND AND DUST TESTING ON A REGULAR BASIS:

-

MILITARY

-

COMMERCIAL

-

INDUSTRIAL

-

AUTOMOTIVE

-

ELECTRONIC

-

AEROSPACE

Dust and Sand Resistance Unveiled: Environmental Testing for Optimal Performance and Durability

Need help evaluating the resistance of materials, equipment, or systems to exposure to sand and dust particles?

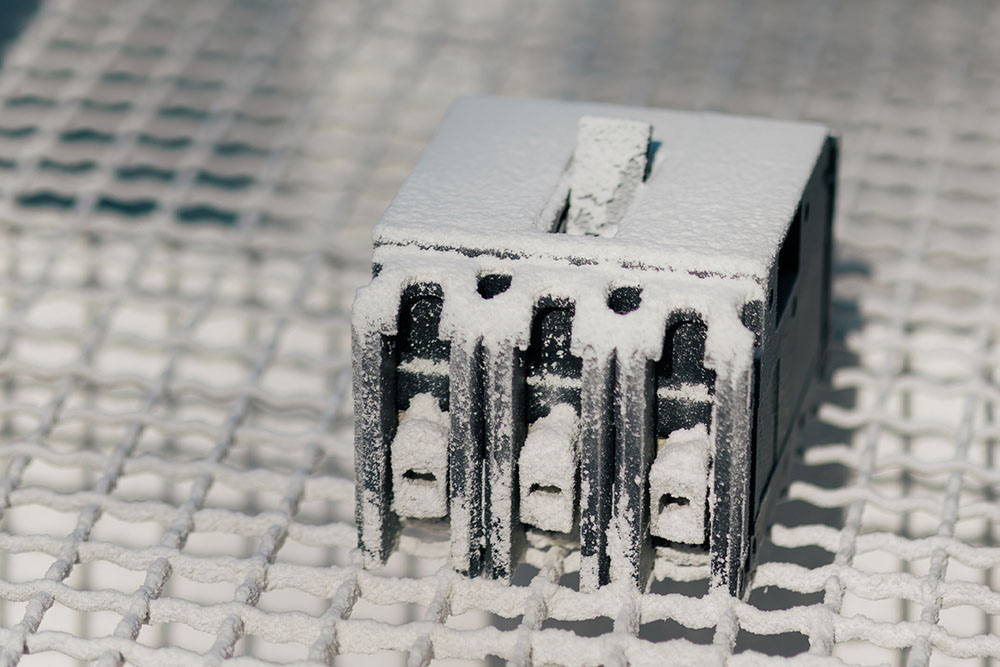

At C&C Technologies our testing is typically conducted to ensure that the equipment or system we’re testing in our lab can withstand the harsh environments commonly found in desert or coastal regions or in areas where sand and dust are prevalent, such as construction sites or mining operations.

If you have a material or product that needs sand and dust testing we have the capacity, knowledge, and capabilities to conduct controlled environmental testing that contains a specified amount of sand and dust particles. The testing can be conducted in our laboratory setting or in the field using our specialized testing equipment.

During our testing process, your equipment or material is typically subjected to high levels of vibration and extreme temperature variations to simulate the harsh conditions found in the field.

The results of sand and dust testing are typically used to identify any weaknesses or vulnerabilities in the equipment or material being tested. This information can then be used to make design improvements or modifications to ensure that the equipment or system is better suited for use in environments with high levels of sand and dust.

Some common methods of sand and dust testing include the MIL-STD-810G test method, which is a standard used by the U.S. Department of Defense to evaluate the environmental durability of equipment and materials.

Other test methods include the IP5X and IP6X test method, which is used to evaluate the protection against dust ingress, and the ISO 20653 test method, which is used to evaluate the protection against water and dust ingress.

Overall, sand and dust testing is an important process for ensuring that equipment and materials can withstand harsh environmental conditions and continue to perform reliably over time.

Dust and Sand Resistance Unveiled: Environmental Testing for Optimal Performance and Durability

Need help evaluating the resistance of materials, equipment, or systems to exposure to sand and dust particles?

At C&C Technologies our testing is typically conducted to ensure that the equipment or system we’re testing in our lab can withstand the harsh environments commonly found in desert or coastal regions or in areas where sand and dust are prevalent, such as construction sites or mining operations.

If you have a material or product that needs sand and dust testing we have the capacity, knowledge, and capabilities to conduct controlled environmental testing that contains a specified amount of sand and dust particles. The testing can be conducted in our laboratory setting or in the field using our specialized testing equipment.

During our testing process, your equipment or material is typically subjected to high levels of vibration and extreme temperature variations to simulate the harsh conditions found in the field.

The results of sand and dust testing are typically used to identify any weaknesses or vulnerabilities in the equipment or material being tested. This information can then be used to make design improvements or modifications to ensure that the equipment or system is better suited for use in environments with high levels of sand and dust.

Some common methods of sand and dust testing include the MIL-STD-810G test method, which is a standard used by the U.S. Department of Defense to evaluate the environmental durability of equipment and materials.

Other test methods include the IP5X and IP6X test method, which is used to evaluate the protection against dust ingress, and the ISO 20653 test method, which is used to evaluate the protection against water and dust ingress.

Overall, sand and dust testing is an important process for ensuring that equipment and materials can withstand harsh environmental conditions and continue to perform reliably over time.

COMMON INDUSTRIES THAT UTILIZE SAND AND DUST TESTING ON A REGULAR BASIS:

-

MILITARY

-

COMMERCIAL

-

INDUSTRIAL

-

AUTOMOTIVE

-

ELECTRONIC

-

AEROSPACE

MAIN STANDARDIZED DOCUMENTS

-

MIL-STD-810H

-

MIL-STD-883

-

MIL-STD-202

-

IEC 60529

-

SAE J1455

-

JESD22-A101C

Want to talk to a C&C Technician to assist you in setting your parameters?

Contact us today to learn more about C&C Technologies and how we can help you achieve your testing goals.

This site is protected by reCaptcha and the Google Privacy Policy and Terms of Service apply.